3D Print

Materials

VisiJet M2 CAST – MJP Material

100 % real wax patterns for casting patterns in almost any metal from precious gold to steel. Melts like standard casting waxes, with negligible ash content for defect-free castings.

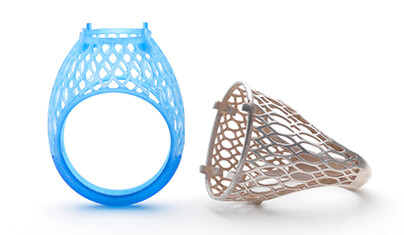

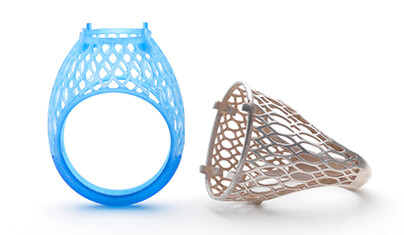

VisiJet M3 Navy – MJP Material

Blue rigid plastic with entry-level set of mechanical properties for general purpose prototyping applications. Create high-fidelity parts you can rely on.

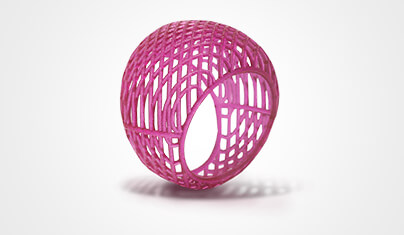

Accura® Amethyst – SLA Material

An accurate, high-resolution master and expendable pattern material optimized for jewellery manufacturing.

DL260 – SLA MATERIAL

Mounding resin suitable both for thin & thick models. Delivers extremely smooth surfaces and exceptionally precise & sharp details.

Figure 4® JEWEL MASTER GRY

A versatile master pattern material for high volume jewelry RTV/silicone molds and for prototype/fit models. The material’s high heat deflection temperature (300°C) ensures compatibility with a range of silicones for creating molds used in jewelry casting production workflows.

Applications

- High definition master patterns for making silicone or RTV molds especially for high volume,

mass production of jewelry designs - Snap-fit and stone-in-place testing

- Client fit/try-on models

- Heat deflection temperature: >300 °C @ 0.455 MPa/66PSI

- Micro printing of upto 10 micron

- Meets biocompatibility standard ISO 10933-5 for cytotoxicity

Figure 4® JCAST-GRN 10

Designed for the jewelry casting professional, Figure 4 ® JCAST-GRN 10 produces accurate, reproducible, and highly detailed master patterns for jewelry casting. This high contrast green material is easy to cast with minimal ash and residue.

Applications

- Production master patterns for gypsum investment casting of:

- Rings

- Bracelets

- Suitable for a range of precious metals

- Micro printing of up to 10 micron

Accura 25 – SLA MATERIAL

Accurate and flexible plastic ideal for snap-fit assemblies, master patterns for vacuum casting & durable functional prototypes with the aesthetics of moulded polypropylene (pp).

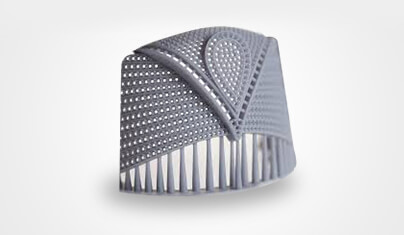

Accura Xtreme – SLA MATERIAL

Ultra-tough grey plastic that resists breakage & handles challenging functional assemblies. Replaces CNC-machined polypropylene and abs. Ideal for master patterns for vacuum casting.

Accura ClearVue – SLA MATERIAL

High clarity plastic with excellent humidity/moisture resistance for a multitude of applications where transparency is key such as headlamps, complex assemblies or fluid flow. Capable of meeting usp class vi.

PA2200 Nylon – SLS MATERIAL

The benefits of printing in nylon far outweigh other 3d printing technologies. Benefits include surprising strength even at 1 mm thick, low cost per cm3 & express production times.

Figure 4 ® RUBBER-65A BLK

A mid-tear strength, production-grade rubber combined with Shore 65Ahardness and a high elongation at break.

Figure 4 RUBBER-65A BLK is a mid-tear strength material for the production of medium, hard rubber parts with slow rebound, for applications such as grips, handles, gaskets, bumpers, seals, vibration dampening components and more.

Applications

- Air /dust gaskets

- Seals and housings

- Vibration dampener and pipe spacers

- Bumpers

- Grips and handles

Figure 4 ® PRO-BLK 10

Figure 4 ® PRO-BLK 10 delivers on the promise of additive manufacturing with true direct, digital production of plastic parts. It is a high precision resin producing parts with a smooth surface finish and sidewall quality.

Applications

- Tool-less, same day production

- Direct production of small black plastic parts; examples include: motor housings, connectors, snap-fits, automotive interior and other general-use parts

- Biocompatible capable per ISO10993-5 and ISO10993-10

Figure 4 ® TOUGH-GRY 15

This durable opaque gray material produces highly accurate components for consumer goods, aerospace and automotive industries, with digital molding productivity and cost-efficiency.

Applications

- Strong functional parts for:

- Automotive styling parts

- Form, fit and function testing

- Durable assemblies and snap fits

- Short-run manufacturing of rigid parts

- Ready for painting or plating

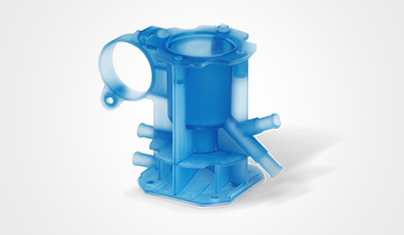

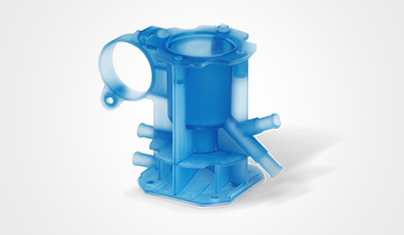

Figure 4 ® MED-AMB 10

Figure 4 ® MED-AMB 10 is a rigid, translucent material for a range of medical and industrial applications, including when biocompatibility, sterilization and/or thermal resistance is required with fluid flow visualization. Capable of meeting ISO 10993-5 and -10 standards for biocompatibility (cytotoxicity, sensitization and irritation).

Applications

- General medical applications requiring biocompatibility, sterilization and/or thermal resistance

- Surgical drill guides, splints

- Fluid handling manifolds

- Visualization and fluid flow models

- Biocompatible*

- Thermal resistance over 100 °C

Figure 4® HI TEMP 300-AMB

Figure 4 ® HI TEMP 300-AMB is an ultra-high temperature plastic for use in applications requiring high heat resistance. With heat deflection temperature of over 300 °C at both low and high stress (HDT at 0.455 and 1.82 MPa), enclosures, stators, molds and the like. It does not require a secondary thermal post-cure.

- High temperature components testing, and general use parts including: HVAC,consumer appliances, motor enclosures, stators, etc.

- Low pressure molding/tooling: expanding foams, rubbers, etc.

- Overmolding

- HDT over 300 °C at both low and high stress (HDT at 0.455 and 1.82 MPa)

- Rigid and translucent

VisiJet M2 CAST – MJP Material

100 % real wax patterns for casting patterns in almost any metal from precious gold to steel. Melts like standard casting waxes, with negligible ash content for defect-free castings.

VisiJet M3 Navy – MJP Material

Blue rigid plastic with entry-level set of mechanical properties for general purpose prototyping applications. Create high-fidelity parts you can rely on.

Jewellery Materials

VisiJet M2 CAST – MJP Material

100 % real wax patterns for casting patterns in almost any metal from precious gold to steel. Melts like standard casting waxes, with negligible ash content for defect-free castings.

VisiJet M3 Navy – MJP Material

Blue rigid plastic with entry-level set of mechanical properties for general purpose prototyping applications. Create high-fidelity parts you can rely on.

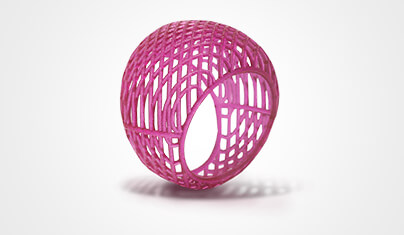

Accura® Amethyst – SLA Material

An accurate, high-resolution master and expendable pattern material optimized for jewellery manufacturing.

DL260 – SLA MATERIAL

Mounding resin suitable both for thin & thick models. Delivers extremely smooth surfaces and exceptionally precise & sharp details.

Figure 4® JEWEL MASTER GRY

A versatile master pattern material for high volume jewelry RTV/silicone molds and for prototype/fit models. The material’s high heat deflection temperature (300°C) ensures compatibility with a range of silicones for creating molds used in jewelry casting production workflows.

Applications

- High definition master patterns for making silicone or RTV molds especially for high volume,

mass production of jewelry designs - Snap-fit and stone-in-place testing

- Client fit/try-on models

- Heat deflection temperature: >300 °C @ 0.455 MPa/66PSI

- Micro printing of upto 10 micron

- Meets biocompatibility standard ISO 10933-5 for cytotoxicity

Figure 4® JCAST-GRN 10

Designed for the jewelry casting professional, Figure 4 ® JCAST-GRN 10 produces accurate, reproducible, and highly detailed master patterns for jewelry casting. This high contrast green material is easy to cast with minimal ash and residue.

Applications

- Production master patterns for gypsum investment casting of:

- Rings

- Bracelets

- Suitable for a range of precious metals

- Micro printing of up to 10 micron

Engineering Materials

Accura 25 – SLA MATERIAL

Accurate and flexible plastic ideal for snap-fit assemblies, master patterns for vacuum casting & durable functional prototypes with the aesthetics of moulded polypropylene (pp).

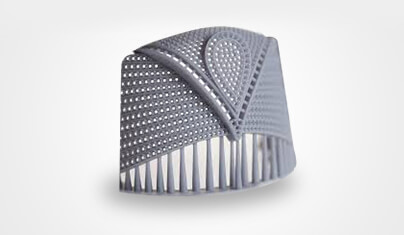

Accura Xtreme – SLA MATERIAL

Ultra-tough grey plastic that resists breakage & handles challenging functional assemblies. Replaces CNC-machined polypropylene and abs. Ideal for master patterns for vacuum casting.

Accura ClearVue – SLA MATERIAL

High clarity plastic with excellent humidity/moisture resistance for a multitude of applications where transparency is key such as headlamps, complex assemblies or fluid flow. Capable of meeting usp class vi.

PA2200 Nylon – SLS MATERIAL

The benefits of printing in nylon far outweigh other 3d printing technologies. Benefits include surprising strength even at 1 mm thick, low cost per cm3 & express production times.

Figure 4 ® RUBBER-65A BLK

A mid-tear strength, production-grade rubber combined with Shore 65Ahardness and a high elongation at break.

Figure 4 RUBBER-65A BLK is a mid-tear strength material for the production of medium, hard rubber parts with slow rebound, for applications such as grips, handles, gaskets, bumpers, seals, vibration dampening components and more.

Applications

- Air /dust gaskets

- Seals and housings

- Vibration dampener and pipe spacers

- Bumpers

- Grips and handles

Figure 4 ® PRO-BLK 10

Figure 4 ® PRO-BLK 10 delivers on the promise of additive manufacturing with true direct, digital production of plastic parts. It is a high precision resin producing parts with a smooth surface finish and sidewall quality.

Applications

- Tool-less, same day production

- Direct production of small black plastic parts; examples include: motor housings, connectors, snap-fits, automotive interior and other general-use parts

- Biocompatible capable per ISO10993-5 and ISO10993-10

Figure 4 ® TOUGH-GRY 15

This durable opaque gray material produces highly accurate components for consumer goods, aerospace and automotive industries, with digital molding productivity and cost-efficiency.

Applications

- Strong functional parts for:

- Automotive styling parts

- Form, fit and function testing

- Durable assemblies and snap fits

- Short-run manufacturing of rigid parts

- Ready for painting or plating

Figure 4 ® MED-AMB 10

Figure 4 ® MED-AMB 10 is a rigid, translucent material for a range of medical and industrial applications, including when biocompatibility, sterilization and/or thermal resistance is required with fluid flow visualization. Capable of meeting ISO 10993-5 and -10 standards for biocompatibility (cytotoxicity, sensitization and irritation).

Applications

- General medical applications requiring biocompatibility, sterilization and/or thermal resistance

- Surgical drill guides, splints

- Fluid handling manifolds

- Visualization and fluid flow models

- Biocompatible*

- Thermal resistance over 100 °C

Figure 4® HI TEMP 300-AMB

Figure 4 ® HI TEMP 300-AMB is an ultra-high temperature plastic for use in applications requiring high heat resistance. With heat deflection temperature of over 300 °C at both low and high stress (HDT at 0.455 and 1.82 MPa), enclosures, stators, molds and the like. It does not require a secondary thermal post-cure.

- High temperature components testing, and general use parts including: HVAC,consumer appliances, motor enclosures, stators, etc.

- Low pressure molding/tooling: expanding foams, rubbers, etc.

- Overmolding

- HDT over 300 °C at both low and high stress (HDT at 0.455 and 1.82 MPa)

- Rigid and translucent

VisiJet M2 CAST – MJP Material

100 % real wax patterns for casting patterns in almost any metal from precious gold to steel. Melts like standard casting waxes, with negligible ash content for defect-free castings.

VisiJet M3 Navy – MJP Material

Blue rigid plastic with entry-level set of mechanical properties for general purpose prototyping applications. Create high-fidelity parts you can rely on.